Automation + Technology

for Core Assemblies

Examples

Engineering

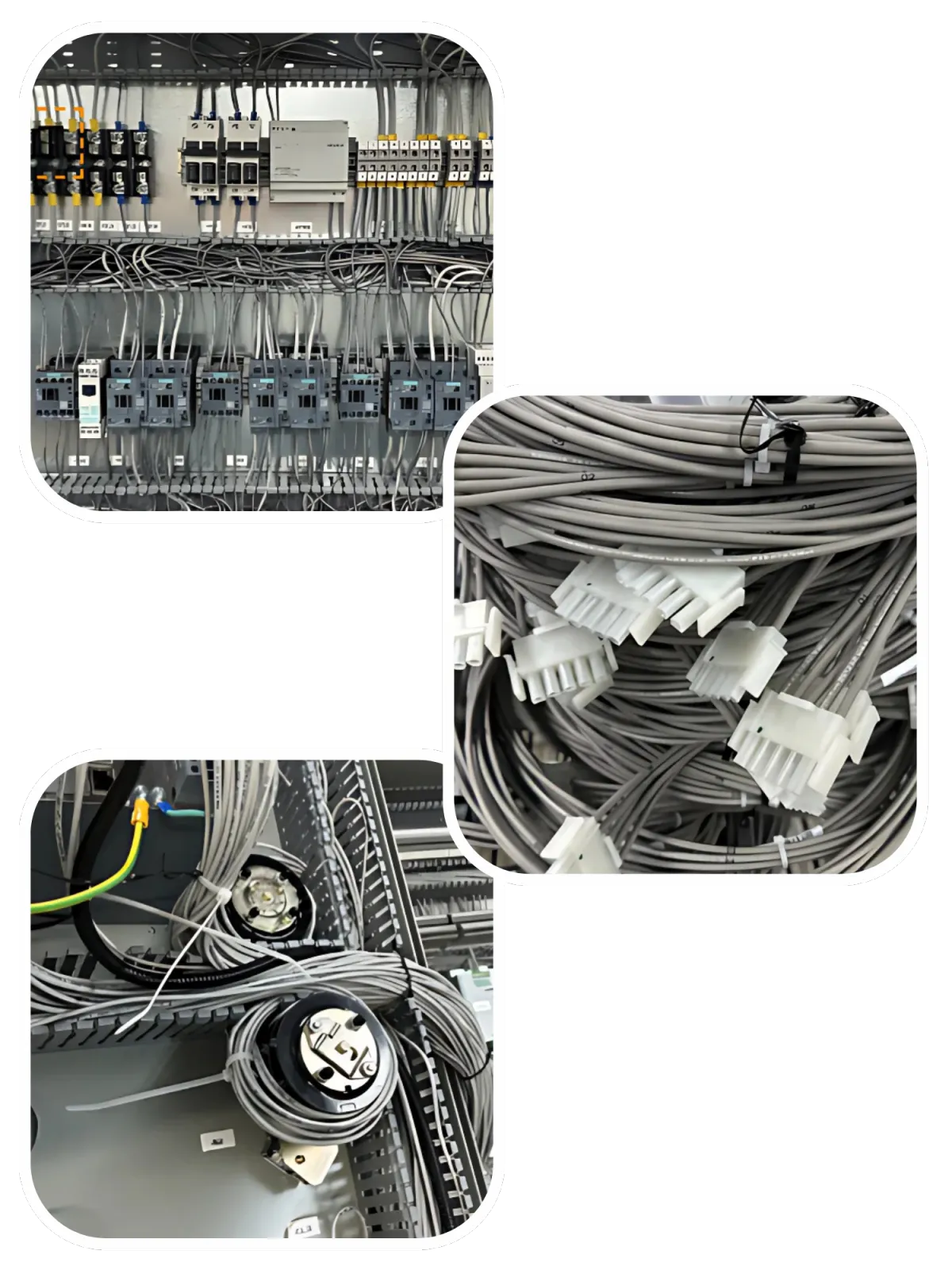

Wire Harness

Control Panel

Why PROSOURCE?

At ProSource, quality is at the heart of everything we do. We take pride in our rigorous quality control processes that ensure every control panel and wire assembly meets the highest industry standards. Our skilled team meticulously inspects every detail, from design to final product, to guarantee flawless performance and reliability for our clients.

We are dedicated to continuous improvement, always seeking new ways to enhance our processes and stay ahead of industry trends. By leveraging advanced technologies and training our team in the latest techniques, we ensure that we consistently deliver products that exceed expectations. Our commitment to quality means we never compromise, no matter the size or complexity of the project.

Customer satisfaction is our ultimate goal, and quality is the key to achieving it. We build long-lasting relationships with our clients by consistently delivering products that are durable, dependable, and precise. Whether it's a standard control panel or a custom wire assembly, you can trust that our commitment to quality will always be reflected in the final product.

CAPABILITIES PROFILE

CORE PRODUCT OFFERING

ENGINEERING SERVICES

Automate your wire harness by using cutting edge technology. No more measuring wire lengths. Let us use logic and automation assist.

WIRE & CABLE ASSEMBLIES

Automate your wire harness by using cutting edge technology. No more measuring wire lengths. Let us use logic and automation assist.

OPEN & CLOSED CONTROL PANELS

UL 508 enclosures are a great plug and play option for switchgear, switchboard, and frames alike. We build it, and you install it with a few bolts.

COMPLEX CONTROL panels & TESTERS

Custom testers and highly complex panels and frames, Top tier connections to all the name brand materials. SIEM, TE, PHX, etc.

160+

Full Time Employees

33.3%

Invest back into the business

$35+

Million in Revenue

What Our Clients Have To Say

Working with ProSource has been an absolute pleasure! They consistently exceed our expectations with on-time deliveries. We’ve always received our control panels and wire assemblies when promised, which is crucial for our production schedule. Their commitment to punctuality and reliability has made them a trusted partner in our operations, and we couldn’t be more satisfied with their service.

We’ve been continually impressed with the superior quality of the control panels and wire assemblies from ProSource. Every product meets and often surpasses our specifications. Their attention to detail ensures that we receive flawless assemblies that are ready to integrate seamlessly into our systems. Their focus on quality has been a game-changer for our business, and we’re confident in their ability to deliver the best.

From start to finish, ProSource provides impeccable service. Their team's dedication to excellence is evident in every aspect of our project, from design to production. The control panels and wire assemblies we receive are always crafted to perfection with no room for error. They have set a new standard for what we expect from a contract manufacturer, and we're thrilled with the consistency and quality they bring to every order.

WE BELIEVE IN EMPOWERING

AND PROTECTING

Quality Assurance

At ProSource, quality is at the heart of everything we do. We take pride in our rigorous quality control processes that ensure every control panel and wire assembly meets the highest industry standards. Our skilled team meticulously inspects every detail, from design to final product, to guarantee flawless performance and reliability for our clients.

We are dedicated to continuous improvement, always seeking new ways to enhance our processes and stay ahead of industry trends. By leveraging advanced technologies and training our team in the latest techniques, we ensure that we consistently deliver products that exceed expectations. Our commitment to quality means we never compromise, no matter the size or complexity of the project.

Customer satisfaction is our ultimate goal, and quality is the key to achieving it. We build long-lasting relationships with our clients by consistently delivering products that are durable, dependable, and precise. Whether it's a standard control panel or a custom wire assembly, you can trust that our commitment to quality will always be reflected in the final product.

Common Industry Issues

Problem

Solution

Problem: Customer doesn't have the ability to communicate quality expectations.

Solution: ProSource operates using IPC-620 and UL508 as a backbone.

Problem: Outdated processes and equipment increase the need for manual manufacturing.

Solution: ProSource Invested millions of dollars in automated equipment. Ex. Komax Omega & Zuken.

Problem: Traceability & Serialization is lacking.

Solution: ProSource has an Identification and Traceability Procedure to manage your needs.

Quality Assurance

At ProSource, quality is at the heart of everything we do. We take pride in our rigorous quality control processes that ensure every control panel and wire assembly meets the highest industry standards. Our skilled team meticulously inspects every detail, from design to final product, to guarantee flawless performance and reliability for our clients.

We are dedicated to continuous improvement, always seeking new ways to enhance our processes and stay ahead of industry trends. By leveraging advanced technologies and training our team in the latest techniques, we ensure that we consistently deliver products that exceed expectations. Our commitment to quality means we never compromise, no matter the size or complexity of the project.

Customer satisfaction is our ultimate goal, and quality is the key to achieving it. We build long-lasting relationships with our clients by consistently delivering products that are durable, dependable, and precise. Whether it's a standard control panel or a custom wire assembly, you can trust that our commitment to quality will always be reflected in the final product.

Common Industry Issues

Problem

Problem: Customer doesn't have the ability to communicate quality expectations.

Problem: Outdated processes and equipment increase the need for manual manufacturing.

Problem: Traceability & Serialization is lacking.

Solution

Solution: ProSource operates using IPC-620 and UL508 as a backbone.

Solution: ProSource invested millions of dollars in automated equipment. Ex. Komax Omega & Zuken.

Solution: ProSource has an Identification and Traceability Procedure to manage your needs.

©2026 ProSource Industries.

All Rights Reserved.

945-312-5342

602 Fountain Parkway, Grand Prairie, Texas

[email protected]